Assembly Compare 3D

Assembly Compare 3D is an easy to use application for quality checking of the sub assembled or the completed product. It finds the smallest detail and compares it to a reference product. The teach-in process is very simple using one approved reference product (Golden Sample) or a reference CAD model. The software supports different 3D scanners for different sizes of products. The scanners range from 200 mm up to 3.7 meters.

Assembly Compare 3D - Features

Assembly Compare 3D is an easy to use application for quality checking of the sub assembled or the completed product. It finds the smallest detail and compares it to a reference product. The teach-in process is very simple using one approved reference product (Golden Sample) or a reference CAD model. The software supports different 3D scanners for different sizes of products. The scanners range from 200 mm up to 3.7 meters.

The software supports multiple measurements from multiple views. In this case either the product or the 3D scanners should be rotated. Hence the Assembly Compare 3D is ideal for robot application. Product handling and quality checking in one process step can be done. The scanner has its own laser lightsource which enables it to be used outdoors or in varying light conditions. Using the average settings the 3D scanning plus the test process takes 1-2 seconds. Using a high end computer with a stronger GPU the process time goes down under 500msec.

- Easy to use/ Zero programming

- Resistant to changes in light conditions

- Fast and reliable detection

- Supporting robot applications

- Accurate, up to 0.2 mm point resolution, and 0.5mm detection accuracy

- Range 0.2 - 3.7 meters

CAD model

Reference Golden DUT / product

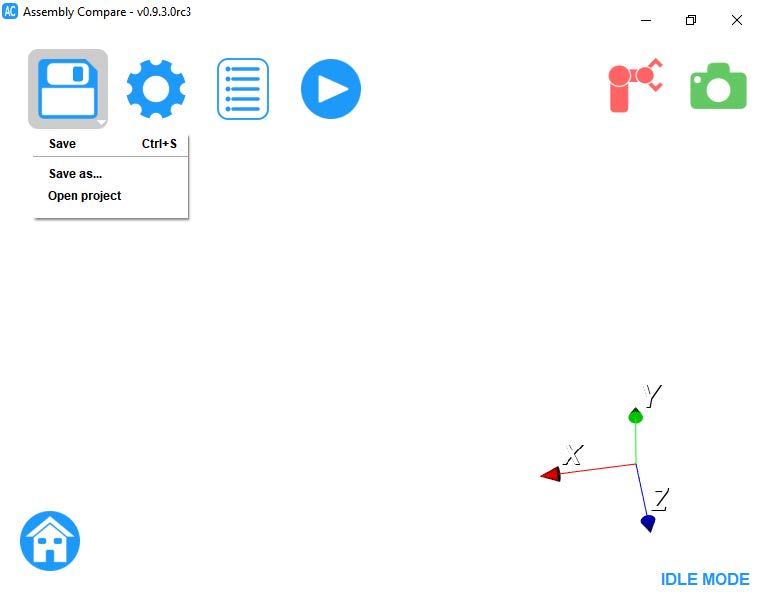

The User Interface

The user interface has a clear style and it has self-explanatory icons. It supports the users in many ways. It indicates the status of the external hardware: the 3D scanner and the robot. It enables loading and running projects remotely, so it supports a totally automated production line.

Authentication:

The projects are password protected. The user can enable this function if needed.

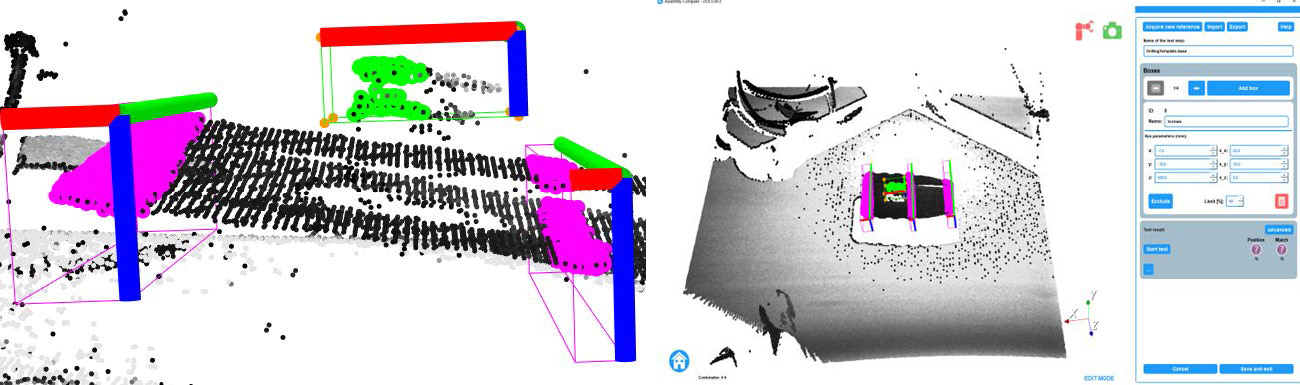

Teach-in process

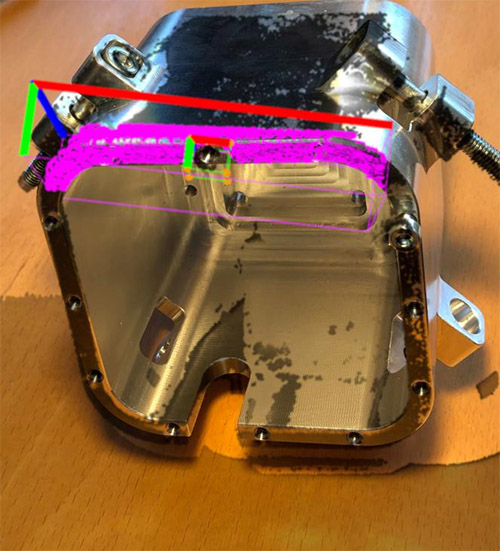

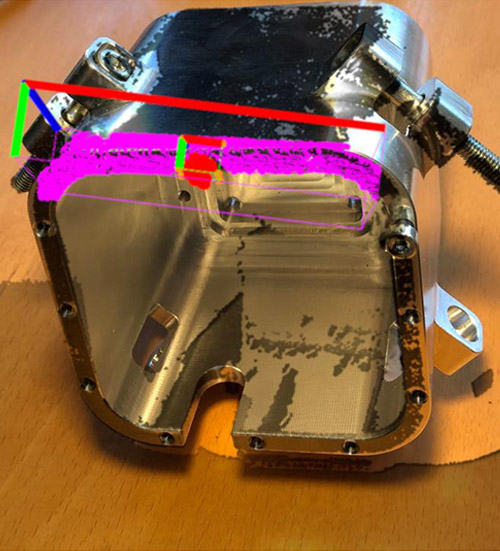

Using a reference product (Golden Sample) the user first makes a 3D scan then draws boxes for product detection and product alignment. The software handles the differences in the cloud points caused by the mechanical misplacing. Then the user draws the test boxes that contain those cloud points the software uses for comparison between the reference product and the product sample from the production. The user can adjust the acceptance limits, them the software makes the comperison and decides the product as FAIL or PASS.

The software supports different camera setups which enables faster computation or higher accuracy. So the user can find the optimal setup for the application.

PASS: Screw exists

FAIL: Screw absent

Network interface

The network interface of Assembly Compare 3D can be reached through a TCP/IP connection, using the IP of the software’s hosting machine, on the port specified in the settings. More details on how to control Assembly Compare 3D remotely can be found in the pdf network_interface.pdf.

Contact us for more information: sales@sanxo.eu

FAQ

1. How can I order SANXO-Scope?

Contact your local distributor or SANXO main office at sales@sanxo.eu

2. How can I try out SANXO-Scope?

Contact your local distributor or SANXO main office in Budapest, where there is a test equipment you can try out.

3. Delivery time of SANXO-Scope

The delivery time is usually 4 weeks after receiving order.

5. How to set up my system after receiving the package?

Please download the Assembly manual and follow its instructions.

6. Troubleshooting my system

Please download the User manual and try to find the solution for your problem. In case you are still not able to troubleshoot your system, please contact us at info@sanxo.eu

METALLURGICAL

microscope

PCB

microscope

CO-EXTRUSION

microscope

JEWELRY

microscope

Contact

Get In Touch