Doctor AOI (PCB inspection)

Doctor - AOI is a cost-effective automated optical inspection concept originally developed to respond to the quality control shortcomings of circuit board production lines. Typical scenarios have included for example factories where an extensive AOI system is implemented into one stage but additional inspections are still in demand, say, post-through-hole soldering. A wide selection of available features and the modular concept of Doctor AOI allow forming a custom tailored solution to augment the factory quality control.

Doctor AOI (PCB inspection) - Basic Features

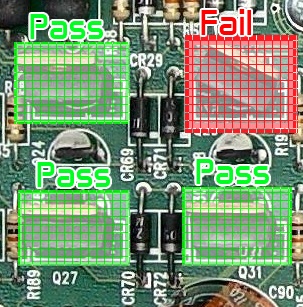

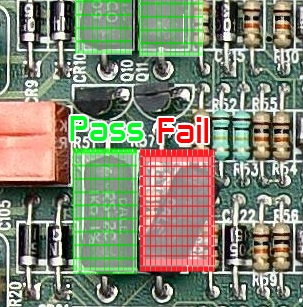

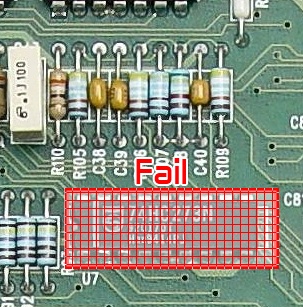

A typical Doctor AOI system is able to identify and/or solve common problems such as:

- Component presence

- Component position and alignment

- Solder quality, various defects such as stains, open/short circuits, thinning of solder etc.

- Barcode/datamatrix and text reading

- Image logging

- Factory automation and site network communications

Doctor AOI can be customized to include any number of available features and implemented at the site both online and offline. The heart of the system, machine vision software Modular-X, enables rapid and flexible application development and the basic features range from presence/absence inspection, quality assessment, code/text reading to various measurement functions. The systems can also be enhanced with multiple and/or moving camera setups and other mechanisms, and the user interface of the individual machines is also subject to customisations.

Example

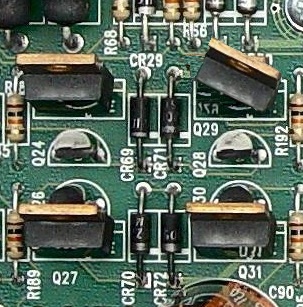

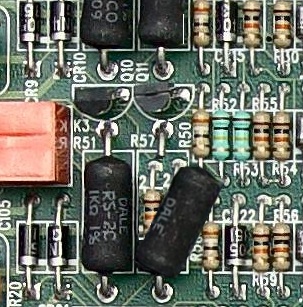

An example Doctor AOI system is an offline inspection station checking the quality of the through-hole solderings, component deformations and the presence of components, particularly those in the vicinity of the through-hole components. Each instance is logged saving the results, images and automatically captured barcode.

This particular system encorporates server-client communication in addition to the above. The setup consists of a fixture, top, bottom and middle cameras, illumination, barcode readers, an I /O module, a PC and a monitor. The PCBs being tested are positioned by a pneumatic rotary table. Safety is ensured by a light curtain. The Modular-X powered inspection application allows easy system upgrading, adding new features to the PCB test script.

Ask for more

Contact our machine vision experts to discuss AOI system implementations for your production line. Our selection and experience cover a broad range of technology, do not hesitate to ask for special customizations.

FAQ

1. How can I order SANXO-Scope?

Contact your local distributor or SANXO main office at sales@sanxo.eu

2. How can I try out SANXO-Scope?

Contact your local distributor or SANXO main office in Budapest, where there is a test equipment you can try out.

3. Delivery time of SANXO-Scope

The delivery time is usually 4 weeks after receiving order.

5. How to set up my system after receiving the package?

Please download the Assembly manual and follow its instructions.

6. Troubleshooting my system

Please download the User manual and try to find the solution for your problem. In case you are still not able to troubleshoot your system, please contact us at info@sanxo.eu

METALLURGICAL

microscope

PCB

microscope

CO-EXTRUSION

microscope

JEWELRY

microscope

Contact

Get In Touch